Maintenance of industrial automation systems

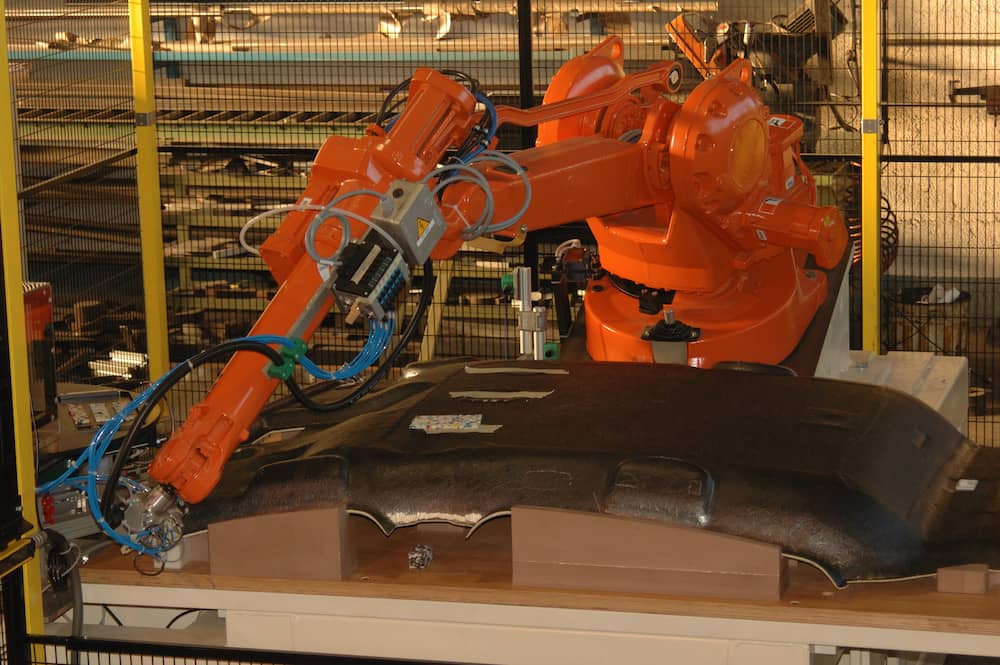

GT Engineering deals with assistance, ordinary and extraordinary maintenance on automatic systems and lines. The assistance service of industrial automation systems is essential to maintain high standards of quality, effectiveness and production efficiency over time.

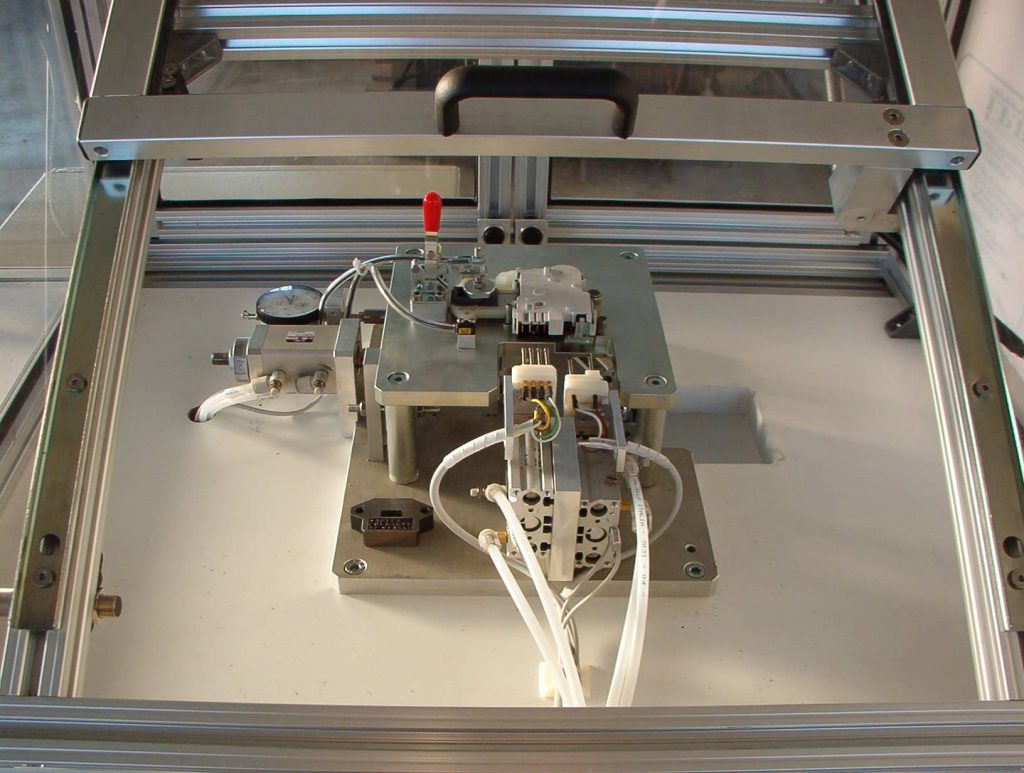

The after-sales assistance guaranteed by GT Engineering is supported by a local diagnostic system and a remote assistance system. This methodology ensures constant monitoring of the system and allows unexpected solutions to be resolved quickly without moving the technicians.

The installation and commissioning of the systems is entrusted to our specialized staff. The after-sales service we reserve for the customer is structured in the training of operators, in ordinary assistance upon request, on scheduled periodic or extraordinary maintenance. We organize training periods for operators and direct interventions if required.

When is maintenance required?

– Implant obsolescence

– Software update

– Modernization of the line or machinery

– Change of production

– Fault on the line, on the machinery or system totally blocked

– System not up to standard or in need of safety.

Scheduled maintenance

GT Engineering offers a periodic preventive maintenance service, in order to keep the performance of plants and applications optimized. This service allows to ensure the conditions of safety and functionality, to detect possible anomalies in advance and to implement the necessary corrective actions of extraordinary maintenance.

Extraordinary maintenance

Extraordinary maintenance can be requested by the customer on all our systems and is also extended to further needs, such as process integration.

GT Engineering specializes in the maintenance, assistance and modernization of industrial plants and existing lines. We provide effective solutions for the optimization of industrial production automation systems.

GT Engineering deals with the overhaul and restructuring of old plants and we carry out interventions for the modernization and improvement of production lines.

Production efficiency solutions

Each industrial automation system can be optimized over time with an adequate and effective management service.

Thanks to the tools that allow us to operate remotely, we can interact with people, machines and robots in real time, reducing the time for diagnosing the problem and intervening quickly on the production line.

How can we help you?

Call us or write us an email